Posted on: 11th February 2016 by Kyle Smith

Historically, inadequate attention to work roll spray cooling configurations when rolling aluminium has significantly reduced flatness and profile controller performance.

Good dimensional quality from rolling mills depends not only on the control system, but also on the spray actuator. The work roll cooling needs to be recognised as a vital part of the rolling process.

The benefits of optimising the cooling arrangement include:

• Improved dimensional control (flatness or profile) from precise axial application of the coolant to the work roll surface. This allows accurate control of the magnitude of the work roll thermal expansion. The degree of improvement will depend on how the actuator improvements are utilised within the control software.

• Improved surface quality from improved oil plate-out and lubrication conditions in the roll gap.

• Increased productivity through the ability to control the magnitude of thermal camber when rolling with fewer passes, larger reductions or running at higher speeds

• Reduced overall coolant flow to achieve a required level of cooling, due to reduced bank-to-bank interactions, controlled spray application and distribution of flow to the entry and exit sides of the rolling mill. Reduced flow also gives a reduction in environmental impact.

Factors to consider in improving the spray actuator when rolling aluminium

The spray impact pattern on the surface of the work rolls is of great importance. This dictates the level of flow required to achieve a desired cooling effect and the control resolution available from switching or pulsing sprays on or off. The more efficiently the coolant is applied, the lower the applied coolant flow required. Alternatively, for a given applied flow rate, an efficient coolant application will give enhanced cooling performance. The axial interaction of nozzles across the work rolls plays a significant role in the ability to locally affect the thermal roll expansion. For this reason the overlap of spray patterns requires significant attention. The initial objective of any work roll cooling arrangement is to remove sufficient heat to maintain a target work roll temperature. As each mill is different, may roll different product ranges and have different pass parameters, each cooling arrangement needs to be tailored to suit.

The nozzle configuration and flow must be calculated from the heat input to the roll, which necessitates a suitable roll gap model. It is not sufficient to calculate flow rate simply from installed motor power as is sometimes done. The overall effectiveness of the sprays depends critically on the impinged area, interaction between spray banks and the presence of layers of coolant on the roll surface. It is not possible to derive the effectiveness from the nozzle flows alone. It is generally best for the pattern to occupy as large an area as possible. The net cooling is increased in this way as is the degree of control of the cooling via spray nozzle switching. When spray banks are placed close to each other on the roll surface, the net effect of the two is generally less than the sum of their separate effects. This is because they may share a portion of the roll surface. Adequate spacing of the rows of coolant is therefore critical. If rolls rotate slowly and the cooling coefficients are high, then the roll surface is chilled under the sprays which can reduce the cooling effectiveness by 50% or more. It is important to allow for this effect in designing the spray system. This requires a model of the circumferential temperature distribution around the roll.

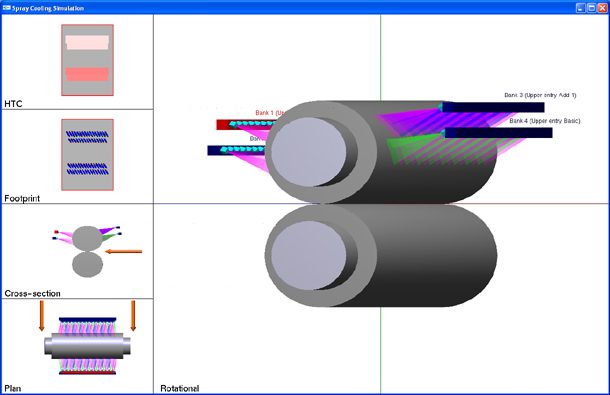

The Innoval Spray Impact Model (ISIM) has been designed to enable the optimal spray arrangement for any case to be derived quickly and accurately and has contributed to proven improvements in the operation of many mills around the world. ISIM is not only applicable to rolling aluminium; it can be used for other metals such as steel.

ISIM is one of a suite of eight aluminium rolling process models which we have developed to optimise rolling aluminium. If you’d like to learn more about how we can support your rolling operation, please click here.