Background

Meyer Aluminium Ltd (Meyer) is the world’s largest producer of aluminium circles, with sales in more than 40 countries. Circles account for approximately 85% of the company’s output and they are widely used in applications such as cookware, reflectors and ventilation.

Meyer, which operates rolling mills in both Hong Kong and Thailand, wanted to improve quality through improving their in-house roll grinding facility. They had already acquired a good quality 2nd-hand roll grinding machine, but needed assistance in ensuring the foundation was correctly designed to avoid problems with resonant vibrations. Meyer also wanted to ensure good operating practices were developed for the grinding process.

How we were involved

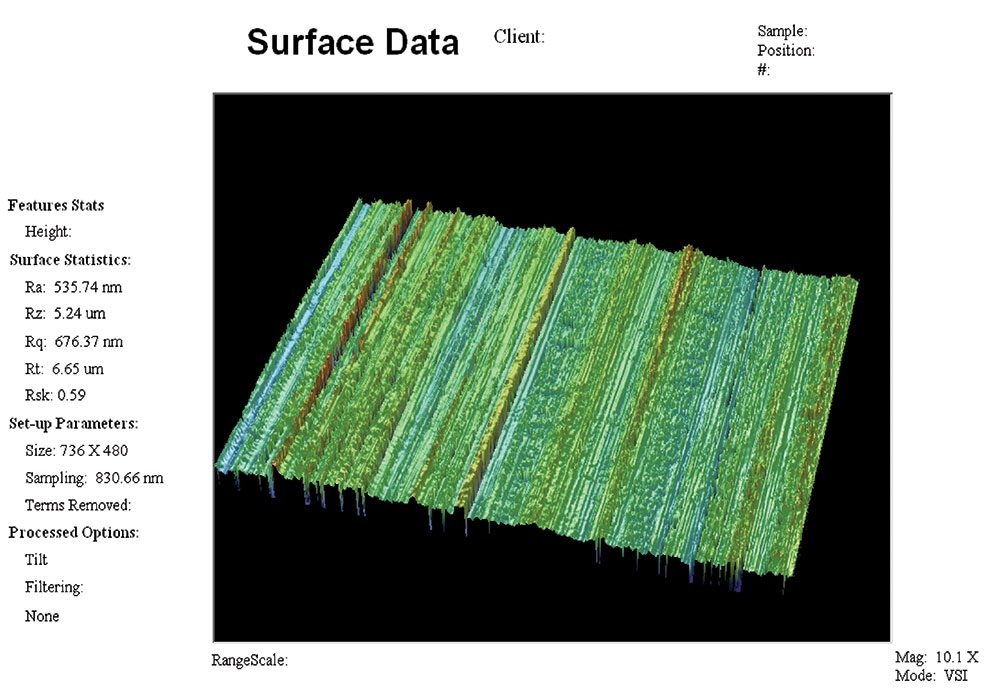

During the first phase of this project Mark Foster, a surfaces and lubrication expert from our Materials Development team, led a visit to Meyer’s plant in Hong Kong, together with one of Univib’s vibration experts. They assessed potential locations for the new grinder, and discussed the specifications for both the existing and the new grinders. Mark and the team also observed the roll grinding operation and made a record of the grinding practices. Roll replicas were taken during the grinding of a cold mill work roll to trace the development of the surface topography. These replicas were then examined by our labs in Banbury.

Outcome

The vibration analysis ensured that the grinder was placed in a suitable location. It is now working successfully and has achieved the objectives Meyer set for it. Mark’s observations, together with discussions on the requirements for future products, complemented the surface studies. Mark was also able to make valuable suggestions for the operating practices on the new and existing grinder.

Services Involved

- Process Improvement

- Rolling

- Surface Treatment

This case study appears as an article in the 2011 edition of ‘innform’; the newsletter of Innoval Technology.

The roll replicas gave us some valuable information about our grinding process. These, together with the other recommendations, have enabled us to significantly improve our grinding operating practices. I’m very happy with the outcome of this project and we will continue to work with Innoval in the future.

Kenneth Yuen, Technical Manager, Meyer Aluminium Ltd