Background

Because of the combination of product and process expertise at Innoval, we often support companies working towards automotive or aerospace qualification. As anyone who’s experienced this knows, it can be a very long and difficult process. However, by involving Innoval’s experts, it’s possible to fast-track the learning process to qualify sooner. Alro, a leading supplier of aerospace plate, is testament to this.

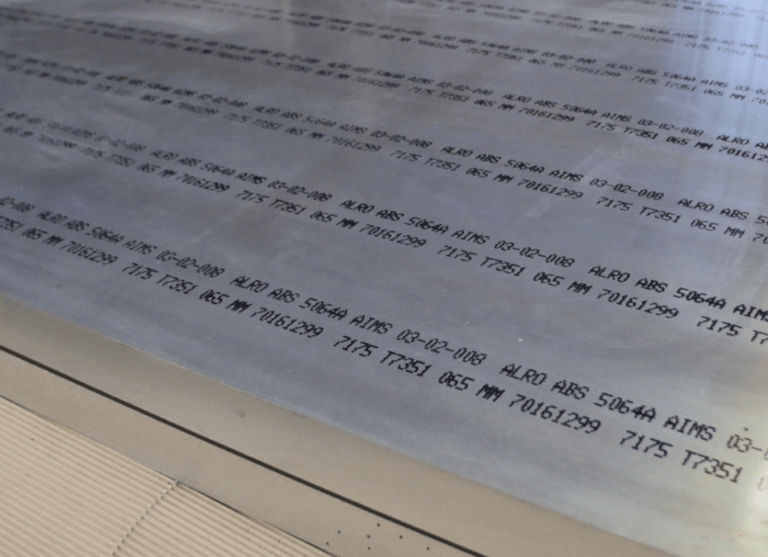

Alro is the largest aluminium producer in Continental Europe (excluding Russia and Scandinavia). It is a subsidiary of Vimetco N.V., a global, vertically-integrated primary and processed aluminium producer. Several years ago Alro decided to enter the aerospace market. As a result, they asked us to help make the aerospace qualification process as quick and efficient as possible.

How we were involved

Gary Mahon, a metallurgist, and Kyle Smith, one of our aluminium rolling experts, worked with the team at Alro over three visits.

Before they arrived in Slatina, Gary and Kyle examined Alro’s Standard Operating Practices (SOPs) from casting composition through to final testing. From this they were able to give advice on what to do to obtain specific properties compatible with a standard aerospace plate process route. Once on site, Gary and Kyle collected process data, made observations and talked to the operators to compare actual practice with the SOPs. In addition to this, they explored contingency practices.

On the practical side, Kyle provided recommendations to optimise the rolling equipment in order to achieve the required product properties. He studied gauge control as well as surface and temperature control. Gary focused on microstructural analysis throughout the entire process. This included where the samples were taken from, how they were measured and what they looked like.

At the solution heat treatment and quench stage, Gary and Kyle made recommendations to modify the standard practices. This would enable Alro to produce a range of thicknesses. For this they used the Innoval Quench Model.

Outcome

Approximately one year after our work with Alro, they received approval to supply a leading aerospace manufacturer and have been doing so ever since. Furthermore, we’re pleased to report that our relationship with this successful company is as strong as ever with an on-going programme of work.

Services Involved

- Aluminium Rolling

- Innoval Quench Model

- Materials Development

This case study appears as an article in the 2018 edition of ‘innform’; the newsletter of Innoval Technology.

Gary and Kyle made sure we started off right with the optimum composition for our processes. Also, they gave us the expectations for each stage from a metallurgical point of view. Involving the Innoval team definitely short cut our road to aerospace qualification.

Gheorghe Dobra, General Manager Alro S.A.