Posted on: 21st April 2016 by Chris Pargeter

It is now accepted that aluminium rolling lubrication strongly influences both mill productivity and metal quality. Following on from our last blog post, we will now introduce you to aluminium rolling lubrication for Cold & Foil Rolling and Water-Based Cold Rolling.

Cold & Foil Rolling

The majority of cold and foil rolling operations use oil-based lubricants, although some mill systems can accommodate water-based alternatives. The base oil represents more than 90% of the total lubricant volume and acts as a solvent for the load bearing additives and a roll-cooling medium. The base oil viscosity has a significant effect on the quantity of lubricant entering the roll bite and hence rolling efficiency.

Traditional cold rolling lubricants comprise a base oil, load bearing additives and anti-oxidants. The base oil must have a suitable viscosity for the mill duty and a narrow boiling range to minimise both evaporation during use and the risk of staining during annealing of the rolled strip. Refining processes help to ensure compliance with several American Food and Drug Administration standards and have the advantageous effects of increasing flash point and reducing odour.

Load bearing additives must provide the required level of load bearing capacity and frictional control whilst minimising staining during annealing and are typically used at low concentration levels (<10%). Additives are organic compounds containing polar functional groups e.g. alcohols, acids and esters. The presence of these polar groups causes the molecules to adsorb/chemically bond onto metal surfaces and this process is greatly enhanced when aluminium undergoes deformation due to the generation of a highly-reactive, freshly-formed surface.

Water-Based Cold Rolling

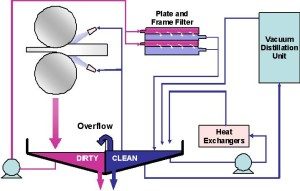

Water-based lubricants have several advantages over oil-based lubricants, including greater heat transfer properties, providing increased cooling of rolls, lower cost, non-flammability and reduced hydrocarbon emissions. However, the use of water increases the risk of surface staining, generation of metal fines and noise from the operation of necessary mill containment systems. Containment systems use a combination of air wipes, vacuum removal and screens to eliminate water staining. A larger lubricant volume and more elaborate filtration are required with these lubricants and there is also a reduced tolerance to process variations.

Water-based lubricant formulations include emulsions of conventional oil-based formulations and solutions in which the load bearing additives are water-soluble at room temperature, but insoluble at roll bite temperatures. Blends of polyoxyalkylene modified alkanolamines and phosphate esters that reduce surface staining are commercially available. Finally, systems where the lubrication and cooling functions are separated by applying oil-based lubricant on the entry side and cooling water on the exit side of the mill have also been exploited.

Getting the lubricant right for your product and process is critical. For information about how Innoval can help with aluminium rolling lubrication, click here.