Posted on: 22nd May 2017 by Kyle Smith

Equipment developments in the world of remelting mean that the traditional process route may be changing. In a departure from the style of our other blogs, I’d like to use this one to pose a question. Do you think we’re about to see the end of the holding furnace when melting uncoated/clean scrap in a typical remelt?

The traditional route

The traditional aluminium remelt processing route for melting uncoated scrap typically involves the following equipment:

- A melting furnace/s for melting solid metal/scrap and alloying it to the target composition.

- A holding furnace in which metal treatment to reduce alkali metals or remove inclusions takes place. Occasionally there are also small alloy “trim” additions.

- A casting pit for pouring molten metal from the holder into moulds to produce slabs. Often there will be some additional equipment (degassers and/or filters) between the holder and the casting pit to improve the metal cleanliness, remove sodium/hydrogen etc.

The holding furnace can also decouple the melting furnace from the casting pit to enable the melting furnace to maximise its output.

Combined melting and holding furnace

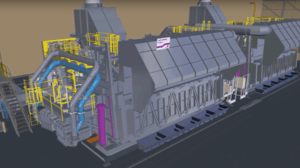

A more recent trend however has been to use a tilting melter/holder. This combines the operations of both furnaces to achieve steps 1 and 2 above. An example of such a furnace can be seen via this link and in Figure 1.

There have been many advances in furnace charging equipment and molten metal treatment over recent years. Taking these into account, it’s generally thought that the operational advantages of a tilting melting/holding furnace are as follows:

- Reduced ongoing maintenance costs particularly refractory wise.

- Reduced melt loss. The transfer from melter to holder typically generates at least 0.4% loss.

- Improved energy efficiency. There’s only one furnace to keep hot and no heat loss during transfer.

- Improved safety due to the elimination of the risk of taphole leakages etc. with a tilting furnace.

- Less complexity when undertaking alloy changes.

CAPEX costs

Whilst the initial cost of a tilting metal/holder should be less than that of separate melting and holding furnaces, to maximise the efficiency of the casting pit, it is likely that you’d need multiple furnaces. Depending upon the casting pit capacity, I anticipate that typically you’d require three tilting melter holders to replace a two melter and two holder configuration. Consequently, the initial capital costs of both configurations may not be significantly different.

The questions is, therefore, to melt uncoated scrap, are the days of the traditional melting and holding furnace configuration numbered, and is the tilting melter/holder the future?

This blog post was originally written by David Humphreys who has now left the company. Please contact Kyle Smith if you have any questions.