Posted on: 22nd June 2017 by Private: Karen Hall

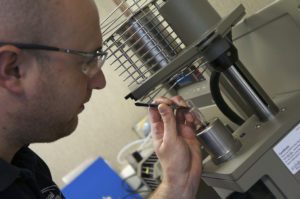

At Innoval, we pride ourselves in the quality of our work and the subsequent reports that we issue. This is especially important to me as Quality Manager for our UKAS ISO 17025 accreditation. It gives our customers the reassurance that our results are accurate and reproducible.

What is ISO 17025?

For testing and calibration laboratories ISO 17025 is the main standard. Its purpose is to implement a quality system which will improve the ability to produce valid, consistent results. Accreditation is the formal recognition of demonstrating this competency. The current version of this standard is ISO 17025:2017.

Working to International Standards

We carry out the majority of the accredited tests/experiments in our laboratories to International ASTM and ISO standards. However, due to the uniqueness of some of our customers’ products, we have created specialised tests. Our in-house procedures cover these.

Keeping up to date with the latest versions of standards is vital, and we use BSI Plus to help us with this. BSI send a monthly update informing us if they have revised or reissued any of the standards on our prescribed list. We automatically receive any standards on this list, so that we always have the most up to date version.

As Quality Manager it is my responsibility to read the standard. I’ll then determine what the changes are and whether they impact on the way we do our testing. Importantly, the revision history of our procedures tracks these changes so that we have full traceability.

Interlaboratory Cross Checks and Proficiency Test Programs

It is a requirement of our UKAS accreditation that we can show that our testing is comparable with that of other laboratories accredited to the same standard. Where possible we take part in recognised proficiency testing (PT) programs. Examples of these are measurement of grain size (ASTM E112), microhardness testing (BS EN 6507-1), qualitative SEM /EDX analysis and qualitative FTIR analysis. We have also taken part in interlaboratory comparison programmes for tests such as Pencil Hardness testing (ASTM D3363) and EXCO testing (ASTM G34). However, there are few recognised PT programs for aluminium products as most are based on steel.

To overcome this and meet our 17025 requirements, we have run interlaboratory cross checks with some of our customers such as Hulamin and Gränges. This is for tests such as aluminium oxide thickness measurements, residual surface carbon levels and electrochemistry experiments (ASTM G69 and G71).

If you are interested in doing any interlaboratory cross checks after looking at our accreditation schedule, please contact me.

Audits

Another key aspect of the ISO 17025 system is auditing. UKAS visit yearly for a surveillance visit, and every fourth year they reassess us. We are currently in the first year of our latest cycle, having passed our reassessment at the start of 2017.

As Quality Manager it is my responsibility to ensure that everything is in place for these visits. This includes making sure that we have appropriate samples available for any tests which UKAS may like to witness. For example, during the latest audit, the assessors increased the number of tests they wished to witness the night before the audit!

After the audit it is my job to make sure that we close out any non-conformities in an agreed time frame. To minimise the number of these, we schedule internal audits throughout the year. These highlight any areas of weakness or ways in which things can be improved. Furthermore, internal audits are important as it’s not possible to witness all tests during an audit by UKAS.

Finally, our ISO 17025 accreditation shows how committed we are to producing quality results which our customers can rely on.