Posted on: 17th December 2018 by Prof. Geoff Scamans

With the rise of the electric vehicle, the case for low carbon aluminium has never been more pertinent. If we’re moving to battery-power in order to reduce carbon emissions from vehicles, building the vehicles themselves from materials that produce high amounts of CO2 during their manufacture seems entirely wrong.

Heavy batteries necessitate lighter vehicle architectures. We already consider that aluminium is the ideal material to accomplish this. However, we now need to think about its embodied carbon and what can be done to reduce it.

In this blog, I will summarise the story so far regarding low carbon aluminium. In my next blog, I’ll talk about what’s happening here in the UK to generate our very own supply of low carbon aluminium.

Recycled aluminium

The aluminium industry has used recycled used beverage cans (UBC’s) for making new can body stock for decades. Novelis is the leading aluminium company in this field.

In March 2015 Hydro acquired WMR Recycling GmbH (WMR) in Dormagen, Germany. This provided Hydro with advanced aluminium scrap sorting technology based on x-ray transmission (XRT). Presently WMR has the capacity to sort 36,000 tonnes of aluminium scrap per year.

Today the plant supplies the Hydro Clervaux facility in Luxembourg with shredded and sorted post-consumer aluminium scrap. It was the first supplier for the production of Hydro’s 75R low carbon aluminium. Hydro 75R contains at least 75% aluminium post-consumer scrap, and has a carbon footprint that is below 2.3 tonnes CO2e / tonne according to their own figures. The properties of 75R match those of primary metal with a dramatically reduced carbon footprint. To date, the production of extrusion billet is the main use for 75R.

Automotive aluminium

Presently most of the aluminium sheet and structural castings used for the manufacture of vehicles are made from primary aluminium. This aluminium has a high carbon intensity which comes mainly from the smelting process. There have been activities to ensure that all this primary aluminium ends up on vehicles.

Novelis has established a closed loop process with various customers such as Jaguar Land Rover and Ford. This uses the production scrap from stamping plants for the creation of aluminium sheet for automotive use. With Jaguar Land Rover, Novelis developed a new grade, RC5754, to accommodate their press shop scrap.

Using information from IAI, the present world average carbon intensity for primary aluminium production is 15.8 tonnes CO2e/tonne Al. The EU average for primary aluminium production is 9.1 tonnes CO2e/tonne Al. This is considerably lower than the average for primary aluminium produced in China from coal-fired electricity generation which can be as high as 22.4 tonnes CO2e/ tonne Al.

Ideally, primary aluminium used for component manufacture for vehicles should be sourced from suppliers using electricity derived from either hydropower or nuclear power. The much better option is not to use primary aluminium, but to use aluminium recycled from end-of-life scrap sources. This aluminium can have an embodied carbon content of less than 0.5 tonnes CO2e/tonne Al.

Comparison with other materials

According to a study by Audi on an individual part basis, the embodied energy in recycled aluminium is lower than that of recycled steel. Furthermore, it is much lower than that of carbon fibre reinforced polymers (CFRP).

Recycled aluminium, as exemplified by the 75R product, is the ideal material for the manufacture of the next generations of electric vehicles. However, there is potential to go further.

Ultra-low carbon aluminium

When Hydro announced their 75R product in 2017 the obvious challenge for us was to evaluate the possibility of making a 100% recycled product. We’d make it entirely out of recycled end-of-life scrap. This type of product would have a carbon footprint of only 0.5 tonnes CO2e/tonne Al.

Fortunately, we already had a supply of suitable end-of-life scrap shredded and sorted through the Innovate UK funded REALITY project. Through this project Novelis, Jaguar Land Rover, Warwick Manufacturing Group, Brunel University, Axion, Norton Aluminium and Innoval are working together to develop suitable aluminium feedstock for high-end automotive applications. There’s more information about the REALITY project here.

The project team cast the scrap into ingots and supplied them to BCAST at Brunel University for DC casting into extrusion logs.

As part of their work on the REALITY project, the researchers at Brunel adjusted the composition of the melt by making additions of copper and magnesium to bring it to within the aluminium automotive body sheet alloy composition range. They then cast extrusion logs using two methods.

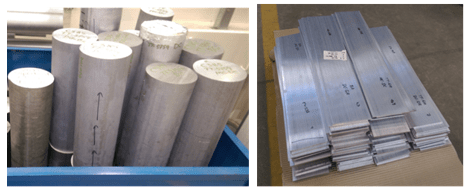

Firstly, they employed the conventional DC casting process with the addition of grain refiner. Secondly, they used a melt-conditioned DC casting process (MC-DC) without grain refiner. Melt conditioning increases the tolerance to iron in the alloy composition. The researchers then homogenised the logs and cut them into billets.

Extrusion produced rectangular planks with a cross section of 4.8mm x 118mm. We then annealed suitable lengths of plank and cold rolled them into strip with gauges of 3.0mm, 1.7mm and 1.0mm. This is where we are at the moment.

Next steps

The next step will be to solution heat treat, quench and age the sheet samples. We will then examine both their microstructures and mechanical properties. Hopefully, the results will demonstrate the potential of making a 100% recycled product. Watch this space!

Of course, in order for a 100% recycled product to be viable, we need a reliable stream of post-consumer aluminium scrap. Here in the UK we have the potential to generate this. I will explain more in my next blog.