Posted on: 3rd March 2017 by Kyle Smith

Failure Modes and Effects Analysis (FMEA) helps you to understand your processes in detail. It highlights the risks and develops the counter-measures. Furthermore, FMEA enables knowledge transfer and develops a multi-disciplined team in one step.

What is FMEA?

Many organisations use FMEA as a step-by-step approach to identifying all possible causes of failure. You can apply the methodology to a new design, a new or existing manufacturing process or a service. A “failure mode” is anything which might result in a defect, total rejection or a fault.

FMEA is not a new tool. The aerospace, nautical and automotive industries have used it extensively for many years. In fact, the Apollo missions used FMEA in the 1960s to help develop their equipment. It was then adopted extensively by the aerospace industry.

In 1974 the US Navy developed the standard MIL-STD-1629. Around this time the automotive industry also latched onto the use of the tool. All of these industries, and more, continue to use FMEA and many international standards require it.

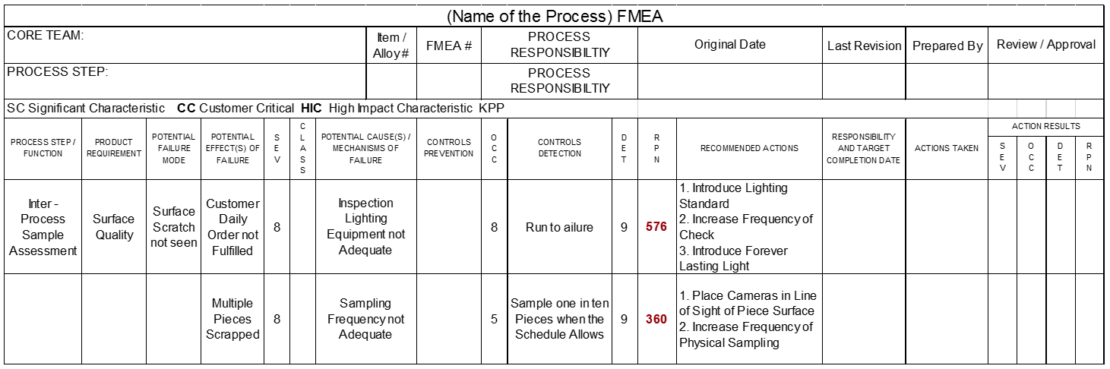

The structure of an FMEA is quite mechanistic. It consists of four distinct sections:

- Severity: here you assess the impact of the failure mode. 1 represents the least concern and 10 represents the most concern.

- Occurrence: assesses the chance of a failure happening. 1 represents the lowest occurrence and 10 represents the highest occurrence.

- Detection: assesses the chance of a detecting a failure. 1 represents the highest chance of detection and 10 represents the lowest chance of detection.

- RPN: Risk Priority Number = Severity x Occurrence x Detection. You will need to define a number that, if exceeded, requires a corrective action. Completing this corrective action will reduce the RPN number.

When to use FMEA

You can use an FMEA in the initial design process when considering new equipment for new processes. This is part of the Reliability Centred Maintenance, or RCM, approach. Alternatively, you can use it with design improvements or process enhancements in existing processes. The purpose of RCM methodology is to develop scheduled maintenance plans that provide an acceptable level of operation, at acceptable levels of risk, in the most efficient and cost-effective manner.

You do not necessarily need to compile new FMEA documents. In established processes you may already have a document that just needs updating or making ‘live’ for the process improvement. When using an FMEA to focus on the process, it is typically called a PFMEA.

When considering a new product introduction, automotive products for example, the PFMEA helps to identify the Key Process Parameters (KPP). It helps to establish a common understanding of the impact of failures, as well as prioritising action items. These might be in reaction plans or corrective actions to minimise or eliminate risks.

Focussing the FMEA from either direction (Reliability or Process) you will find ‘cross-over’ points of failure modes. These will have an impact from either an un-reliable component involved in controlling the processes, or an out of control processes that will affect the reliability of a component.

Who should be involved?

For the best and most positive impact, you need the optimum blend of skills and experience when compiling an FMEA. You should use both internal and external resources, such as subject matter experts, if you need to.

Your resources should come from all stakeholder groups who touch on or are impacted by the process under review. This typically includes operators, technicians, process specialists, supervision and a facilitator.

An additional and substantial benefit of a multi-disciplined team approach when producing an FMEA is the knowledge transfer. Each team member will develop a detailed understanding of the process. FMEA helps to develop a common understanding of the interrelationships that exist between one section of the process and another. It’s important not to consider anything in isolation.

Furthermore, an FMEA can result in much improved job instructions and audit processes. As a result, your processes become much more robust and capable.

Living documents

To maximise their potential, an FMEA needs to be a ‘living’ document that is maintained throughout the life cycle of the product.

If treated as a living document, an FMEA can provide a lot of additional value. It contains useful information when investigating current issues. For example, when identifying the root cause of failures, when speeding up containment and then following up with corrective actions. It also provides data which can then be put into a live database, providing a source of knowledge and process understanding to all levels in the organisation.

How we’ve used FMEA

We routinely employ PFMEA as a structured analytical tool with cross-functional teams. We use it to identify and evaluate the potential failures of a client’s current process. For example, when they’re adopting a new, high value-adding product.

With the lightweighting of automotive vehicles comes the increased use of aluminium in components. The major OEMs require new suppliers to embed FMEAs into their quality systems as a pre-requisite to achieving their basic requirements.

If you want to introduce the FMEA methodology to your organisation, we can help by training your team and by facilitating the process. Please contact us for more information.

This blog post was originally written by Mark Rewaj who has now left the company. Please contact Kyle Smith if you have any questions.