Posted on: 3rd December 2015 by Adam Nadin

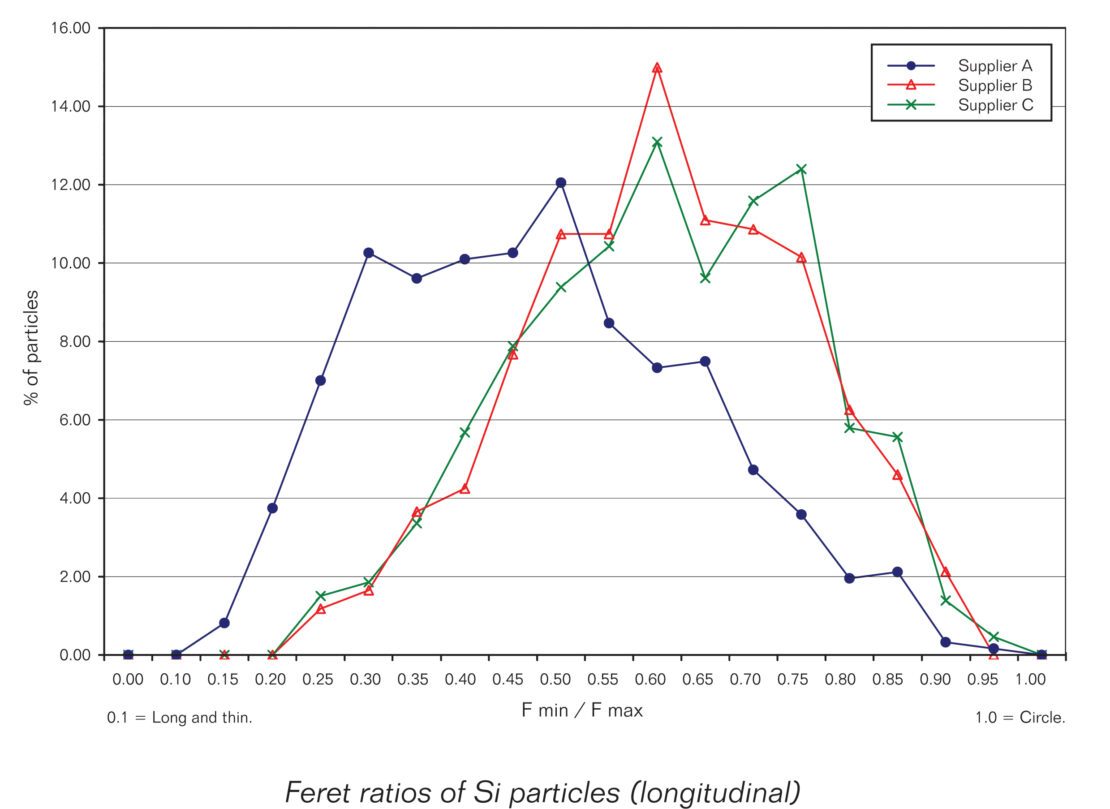

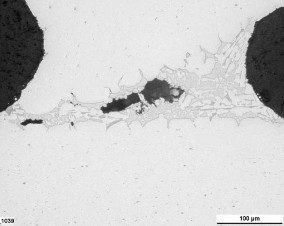

The shape and distribution of the silicon particles in your cladding affect its fluidity once molten. Generally, large silicon particles and those with

a plate-like morphology inhibit the movement of liquid into the joint. The silicon particles can therefore have a significant effect on brazeability. There are often variations in silicon composition within the brazing sheet itself, as well as between suppliers.

We’re able to analyse the silicon particles in samples from each of your suppliers so you can be confident you are selecting the best material for your products. We use optical metallography, together with image analysis, to give you critical information such as Feret ratio, size distribution and equivalent circle diameter of the silicon particles.

We are committed to providing world class expertise in aluminium alloys and brazing technology. Our experts have unique knowledge in materials characterisation and performance, coupled with extensive product and process experience. We’re active in many stages of brazed aluminium heat exchanger supply chain. This gives us a unique view of the industry, and we can supply information on market trends, new materials and processes, and new characterisation/testing techniques to keep you ahead of the competition.

Have a look at our Heat Exchangers Technology page to see how we may be able to help you. You can also download our Aluminium Heat Exchangers brochure here.

If you’re interested in learning more about brazed aluminium heat exchangers, we also have a training course. It covers topics such as metallurgy, corrosion, manufacturing methods and brazing, as well as future developments in heat exchanger technology.

This blog post was originally written by Alan Gray who has now left the company. Please contact Adam Nadin if you have any questions.