Background

With a presence in more than 24 countries, Gestamp is an international group dedicated to the design, development and manufacture of automotive components. The Group specialises in developing innovatively designed products to achieve increasingly safer and lighter vehicles, thereby reducing energy consumption and environmental impact.

In May 2021 we delivered a bespoke online training course on ‘Aluminium Automotive Products’ for Gestamp employees across the globe. Almost two years in the making, and despite the global pandemic, we were able to reach over 230 delegates in 12 different countries. This was thanks to excellent teamwork and cooperation between our two companies.

How we were involved

Aluminium automotive products

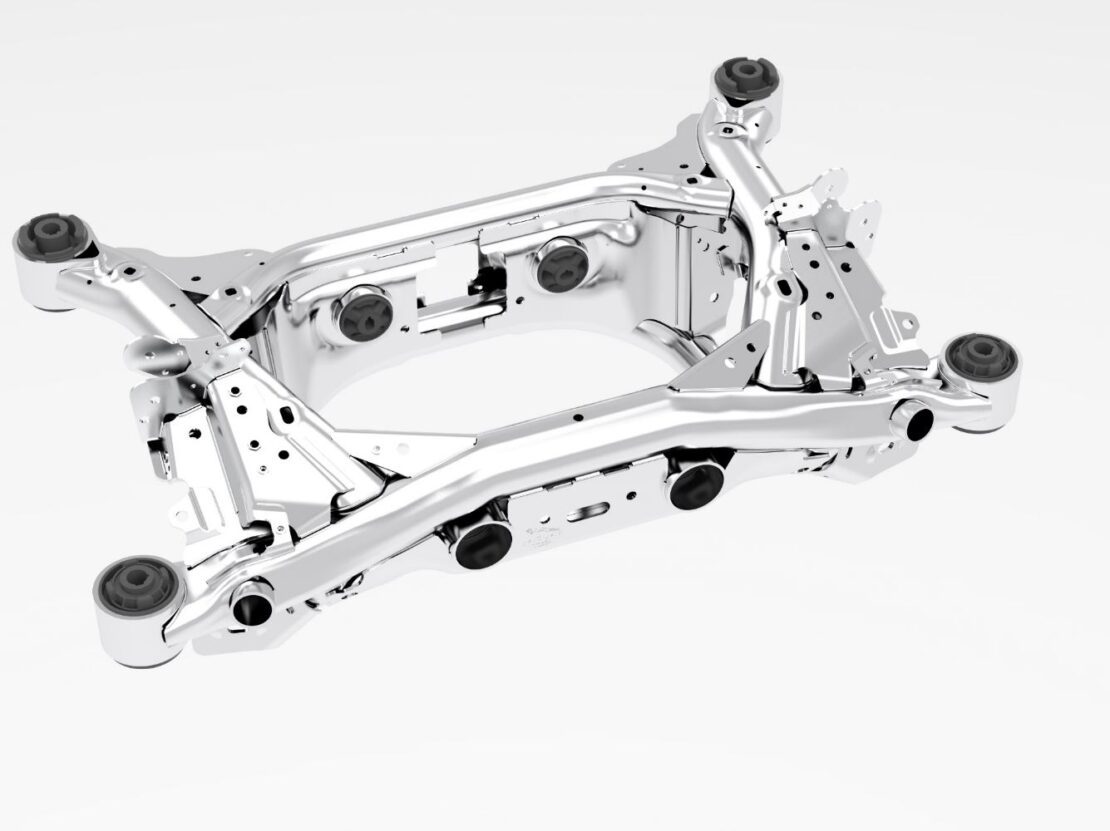

In line with many Tier 1 automotive suppliers, Gestamp is producing an increasing number of aluminium components in response to the automotive OEMs’ drive to produce lighter vehicles. This stems from the need to reduce fuel consumption, and therefore carbon emissions, from fossil fuel-powered vehicles. Lightweighting also allows electric vehicles to accommodate heavy battery packs without compromising vehicle range. Innoval and Gestamp first started to work together on the UKRI / Innovate UK funded ‘RACEForm’ collaborative R&D programme in 2018. Since then, we’ve gone on to form a valuable partnership.

3-day training programme

Gestamp sees employee training and development as vital to their position as global leaders in the automotive supply chain. Consequently, in 2019 Gestamp’s Corporate University Manager, Marta Urdiain, approached Innoval to develop a comprehensive training programme that would give the company’s engineers and non-technical support staff an excellent grounding in aluminium technology as part of their aluminium roadmap.

The brief was to produce a 3-day training programme. The first day of this would introduce aluminium (some basic metallurgy and alloy and temper designations), and give an overview of processing techniques (rolling, extrusion, casting, stamping and joining). This first day would be for everyone. The subsequent two days were to be exclusively for engineers and those employed in a technical discipline. Gestamp wanted us to explore in more depth the topics from Day 1, as well as introduce some new ones, including Surface Treatment and Welding. Once we agreed the course outline, we set about developing the material.

Over the course of several months we worked closely with the Gestamp Chassis team to produce a training course that would be relevant to the products and processes within Gestamp. Where possible, we incorporated examples of both within the training, thanks to the many examples provided by Gestamp. Overall, we wrote material for 14 modules, the majority of which were 1.5 hours long.

Pilot event in Bilbao

At the end of February 2020, once the materials were almost finished, Gestamp invited us to Gestamp Technology Institute (GTI), their impressive training and R&D facility in Bilbao, Spain, to run a pilot event. We presented the course to a group of Engineers from across the various technical disciplines within the company. There was a lot of discussion resulting in some excellent feedback. This then allowed us to refine the materials.

Outcome

Originally, we were hoping to deliver the course over 3 days in Bilbao. However, shortly after the pilot event, the pandemic hit us all and the project was put on hold. Eventually, thanks to some careful organisation by the GTI team, we delivered the course via a series of 2-hour online sessions twice per day (to accommodate different time zones), every day for three-weeks. This was complemented by Mike Bell, Senior Development Engineer, from Gestamp presenting the welding focussed module. It was a huge undertaking but, thankfully, one which paid off. The feedback from Gestamp delegates was exceptional.

During 2021 we have further consolidated our relationship by providing detailed micro-structural investigation and analysis work on a number of different Gestamp research projects. We are looking forward to further developing our partnership and continuing to support Gestamp’s goals of developing and providing aluminium automotive products that offer high value in terms of innovation, price, quality, safety and environmental impact.

Services Involved

- Aluminium surfaces

- Aluminium metallurgy

- Training

This case study appears as an article in the 2021 edition of ‘innform’; the newsletter of Innoval Technology.

Client Quote

“Gestamp diversified into Aluminium chassis over 7 years ago with extensive internal research projects aimed at developing aluminium design and manufacturing capabilities aligned with existing steel core competencies. A fully integrated global approach was adopted with key personnel from Gestamp in Spain, Germany, China and the UK working together with additional contributions from Engineers in North and South America and Japan. Independent micro analysis of weld joint and parent material coupons by Innoval with expert advice on aluminum composition, process and cleaning requirements, underpinned Gestamp’s existing technical & industrial knowledge allowing us to continue to support the rising demand for lightweight chassis structures.”

Phil Potter, Global Innovation Project Manager, Gestamp Chassis.

We aim to provide world class training to support Gestamp’s strategic objectives, keeping up with the latest technologies and materials in order to continually evolve. A main pillar of the Corporate University philosophy is to share the knowledge acquired through experts’ expositions and interactions with champions of use of aluminium, so the Group may apply them in the best possible way. Innoval makes the perfect partner to do so, whilst promoting and laying the basis for a standardized use of the material.”

Marta Urdiain, Corporate University Manager, Gestamp.