Posted on: 23rd March 2016 by Dr. Junjie Wang

Approximately 40%, or 17 million tonnes, of the total world aluminium shipment is in the form of rolled products. This is used in packaging, architectural applications and transportation. All these products require modification of the surface to maintain durable performance.

Surface modification of aluminium involves:

- Cleaning to remove residual oil, oxide films and mechanically disturbed layers

- Pretreatment to provide corrosion protection and modify the surface for enhanced adhesion of coatings or adhesives

- Coating of a protective, decorative or special function finish

Cleaning

There are three general approaches to cleaning:

- Alkaline spray or immersion

- Acid spray or immersion

- Acid electrolytic cleaning

All three provide a surface that is suitable for pretreatment.

Aluminium pretreatment

The aluminium pretreatment process is often integrated with a preceding strip cleaning process, and often a subsequent coating process.

The pretreatment can be either a chemical or an electrolytic process, to replace or modify the natural aluminium oxide film. The chemical process is more usual, with different versions for food packaging applications (to satisfy regulations) and for architectural or transport applications.

Historically pretreatments for coil coated aluminium were chromium (VI) based formulations which provided excellent performance. However, as chromium (VI) is toxic, considerable effort has been deployed to develop more health- and environment- friendly alternative pre-treatments.

Current alternatives include:

- Metal ion analogues to Cr(VI) (Mn, Co) and inorganic molecules reacting with oxidised Al to form mixed oxides (Ti, Zr)

- Film-forming oxides which promote adhesion (silicates, molybdates, vanadates)

- Organic polymers with high complexing capacity.

With earlier conversion coatings, excess solution had to be washed off the metal surface leaving contaminated rinse water as an unwanted by-product. Later, no-rinse systems were developed where a precise amount of pretreatment solution was applied uniformly across the strip and then dried in place.

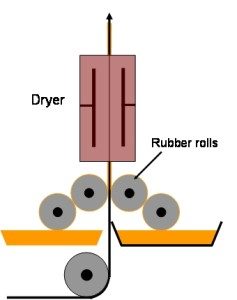

The pretreatment, typically a no-rinse chrome chemical type, is applied to each side of the strip by roller coating. A typical pretreatment is 120 mg/m2 dry coating weight.

The pretreatment is dried, typically by passing the strip through a hot air oven to achieve a metal temperature of approximately 40 to 60°C.

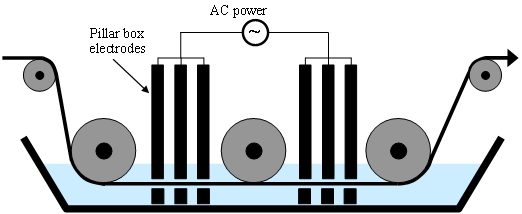

An alternative electrolytic pretreatment process is effectively anodizing in a hot electrolyte using liquid contacts. A cell containing an electrolyte (e.g. 20% sulphuric acid) is divided into 2 or more compartments, with electrodes in each compartment.

By using electrodes with slots through which the strip passes, both sides of the strip are pretreated simultaneously. The pretreatment oxide film is produced whilst the strip is subjected to the anodic half-cycle, and the film is modified by chemical attack during the cathodic half-cycle. Full pretreatment takes about 3 seconds.

After the pretreatment and drying stages, the strip is coated with a lacquer or paint depending on the final product application.

Mechanisms of aluminium pretreatment

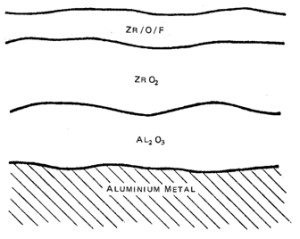

Pretreatment functionality is a combination of one or more attributes.

- Formation of a barrier layer restricting ion, water and oxygen access to the substrate

- Chemical and mechanical stabilisation of the native oxide film

- Improved bonding potential to subsequently applied coatings or adhesives

- Increase of surface area

- Provision of electrochemically derived corrosion resistance

Therefore, both the chemistry and structure of the pretreatment layer play a part in determining performance. Achieving the correct structure can mean the difference between success and failure of the final product.

Aluminium pretreatment represents a small but important cog in a multibillion dollar industry. However, in the twenty-first century, industry requirements for control and minimisation of failure, coupled with increased competition and higher production speeds, places ever increasing demands on pretreated surfaces.

If you need help to choose or optimise a pretreatment system, please get in touch.

This blog post was originally written by Dr Colin Butler who has now left the company. Please contact Dr Junjie Wang if you have any questions.