Posted on: 17th November 2021 by Kyle Smith

Our parent company, Danieli, is exceptionally well known within the global steel rolling industry. However, here at Innoval, it’s our aluminium rolling expertise that sets us apart.

Members of our Process Group spend most of their time helping our clients with anything from optimising their mill set-ups or assisting with quality issues, to mill feasibility studies and designing new plants.

However, what most people don’t realise, is that many of our services are just as applicable to other metals industries, such as the steel rolling industry, as they are to the aluminium industry. This blog briefly describes three of them.

Mill vibration problems in steel rolling

All machines vibrate during operation. However, only a few of these vibrations cause problems to the product or the machine itself. Typically, the most damaging vibrations involve a natural resonance of the machine which significantly increases the motion of critical components. Rolling mill vibration, whether it’s an aluminium or steel mill, is no different.

The most damaging modes of mill vibration involve some very specific natural resonances of the mill stand. If no structural resonances are excited, then the vibration amplitude is simply a consequence of the way the mill responds to a cyclic exciting force acting at a particular location within the mill. Our blog ‘Mill Vibration Phenomena during Cold Rolling’ describes the different modes of mill vibration.

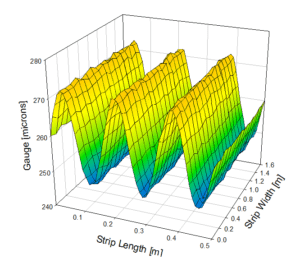

Third octave gauge chatter and fifth octave chatter are two common forms of mill vibration that are difficult to solve. Both can cause significant strip quality issues if they occur on any mill.

There is always a source of vibration responsible for fifth octave chatter, which causes chatter marks on the strip. Consequently, a solution can usually be found to this type of problem. You can read more about chatter marks and how we go about solving them in our blog ‘Roll and Strip Chatter Marks; 5th octave chatter’.

Mill vibration model for steel rolling

There are various ways to solve mill vibration problems and increase the threshold rolling speed of cold mills. Thankfully, we have a lot of experience in this area. One of the tools we use to do this is the Innoval Mill Vibration Model. This vital tool assists in the solution of rolling mill vibration problems faced by the entire metal rolling industry. The model uses available mill data to predict all the key natural resonant modes of vibration of any rolling mill.

We also have tools to reverse-engineer the cause of chatter based on the chatter pitch and the mill stand speed, using the data from the rotating components in the stand and drive systems.

Optimising spray cooling systems

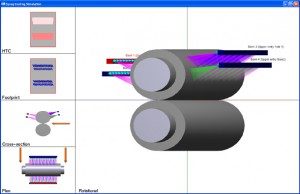

Within our arsenal of process simulation tools is the Innoval Spray Impact Model (ISIM), and it’s one of our most frequently used models. ISIM is a precision tool for modelling the effectiveness of rolling mill spray cooling systems. We use it to accurately evaluate our clients’ current equipment set-up, as well as using it to design new spray headers to meet the challenges of modern rolling mills.

ISIM simulates the spray cooling of rolls in a rolling mill, whether it’s an aluminium or steel mill. Whatever the metal, roll temperatures during rolling are vitally important for lubrication and dimensional control – both profile and flatness.

The inputs to ISIM include the geometry of the sprays and their flow rate. The results reveal the effectiveness of cooling and ultimately the temperature of the rolls during the rolling process.

Insightful findings such as these mean that we are world leaders in roll cooling spray bar design. Because of this, spray system and mill manufacturers come to us for our modelling capabilities when designing new systems.

Life Cycle Assessment

Life Cycle Assessment and Sustainability Analysis are becoming ever more important. This is because the environmental impact of products and services is increasingly in the public’s consciousness, as well as the political arena. Furthermore, this focus on sustainability is coming from investors as well as consumers. It is, therefore, vitally important to understand the environmental impact of your product or service. That’s where Life Cycle Assessment comes in, and it’s a service we offer at Innoval.

Life Cycle Assessment studies span all materials and sectors, and there are many applications. They include product development, identifying opportunities to improve environmental performance, strategic planning, and decision-making. Furthermore, there are marketing reasons such as for an ecolabelling scheme or to make an environmental claim. Our blog ‘Life Cycle Assessment and Sustainability Analysis’ explains what’s involved.

If you’re from an industry other than aluminium, such as steel, please get in touch as you might be surprised how we can help you. To date, we’ve helped companies that roll copper, magnesium, zinc, titanium and steel improve their operations.

This post was originally written by Helen Forrest who has now left the company. Please contact Kyle Smith if you have any questions.