Posted on: 29th July 2016 by Kyle Smith

Recently we posted a blog about using the Innoval Rolling Model to determine work roll camber. This week I’m going to describe how you can use our strip quench model to increase productivity.

Strip quench model

The Innoval Quench Model is one of Innoval’s unique process models. The beauty of all our models is that they are based on physics. The models calculate their results from first principles using complex physical equations. As a result, they’re an accurate simulation of reality at all stages of the process.

Our models enable accurate prediction of process parameters that you can’t normally measure. For example, the temperature in the middle of an ingot during preheating. It’s even possible to take measurements beyond the normal working limits of a piece of equipment. We say it’s like being able to ‘see inside’ a process.

As you can imagine, this is incredibly useful in many situations. For example, the models can help when unforeseen stoppages lead to changes to the normal processing parameters. Other examples include the design of a new process, or when optimising an existing one.

Changes to the strip cooling

In this example we shall look at how our strip quench model can be used to determine a productivity improvement. We’re going to use it to investigate changes to a strip cooling system that you might find on a hot reversing mill.

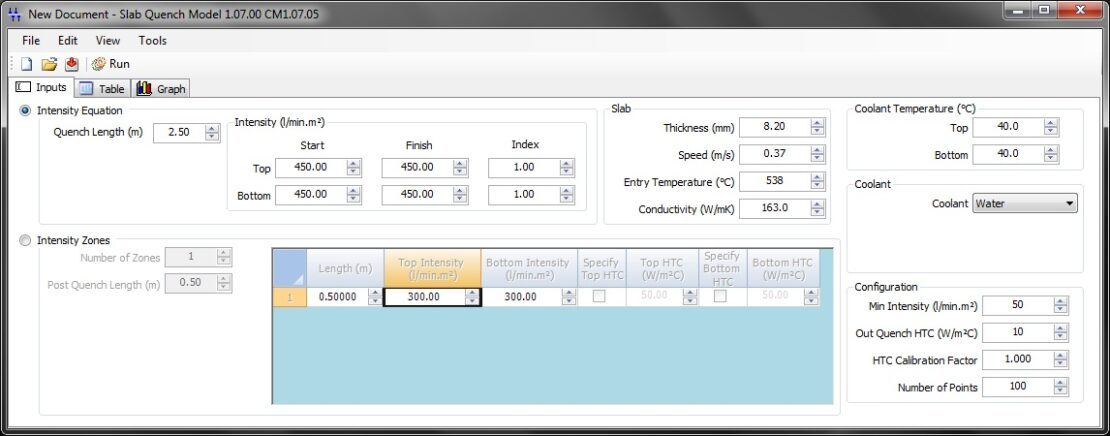

The first thing to do is to set up a model of the existing process. You simply input parameters such as spray intensities, strip speeds and temperatures into a user-friendly graphical interface.

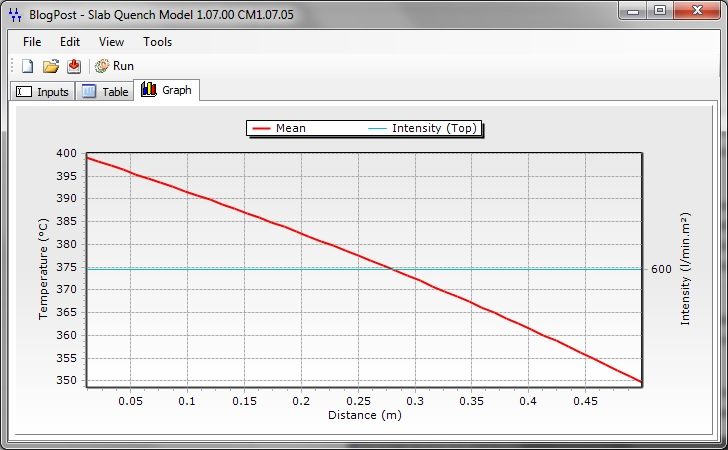

Once this has been done the model will produce a plot of the strip temperature through the quench. This corresponds to the strip cooler’s performance for the current process.

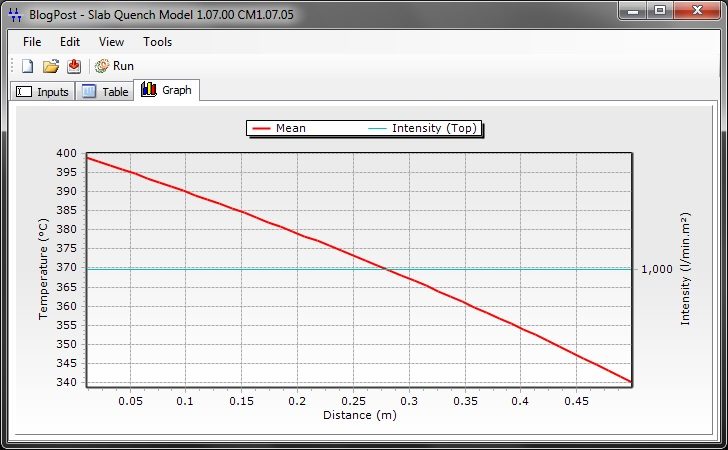

Let’s imagine that recent changes to the roll cooling system on the mill have led to spare coolant pump capacity. It may be possible to achieve the same temperature drop at a faster strip speed by improving the performance of the strip cooler. Increasing the intensity from 600 to 1000 l/(min*m²) for example provides for around 10°C of additional cooling in this case.

This equates to around a 15% speed increase in order to achieve the original process exit temperature from the quench.

Holistic approach

Of course, this higher speed may increase the strip bite exit temperature due to an increased rate of deformation. Consequently, this could limit the effectiveness of the change, so we would investigate the entire mill using the Innoval Rolling Model. This emphasises the need for a holistic approach, which we use here at Innoval when assessing a process. Only then can the best outcomes be achieved by any optimisation exercise.

Optimising your rolling process to increase productivity, improve quality or save energy is much quicker and simpler with aluminium rolling process models. We believe our suite of process models are the most accurate available to the industry today. This is because, alongside the physics of the process, they incorporate the comprehensive knowledge and understanding of aluminium that is unique to Innoval. If you’d like to know more, please get in touch.

This post was originally written by Dr Timothy Clemson who has now left the company. Please contact Kyle Smith if you have any questions.